Neodymium Magnets

e-Magnets has a wide range of neodymium magnets, readily available and suitable for a variety of different applications.

Neodymium magnets are the strongest type of commercially available magnet, offering incredibly high performance.

We stock them as discs, rings, blocks, spheres and other variations. e-Magnets has a wide range of magnets, suitable for an even wider range of applications.

Buy Neodymium Magnets online with e-Magnets™

Neodymium Iron Boron Magnets (“”Neo””, NdFeB or Neodymium) are made from an alloy containing, amongst others, the elements Neodymium, Iron and Boron (NdFeB). The NdFeB magnets are the strongest type of magnet commercially available and are manufactured in a wide range of shapes, sizes and grades.

We offer 53 grades of licensed standard corrosion resistance Neodymium Iron Boron Magnets and now an additional 72 grades of improved corrosion resistance Neodymium Iron Boron Magnets, each type with 30 types of coating finish for each grade (125 grades in total with 34 finishes – 4250 combinations).

How does a Neodymium magnet work?

The Neodymium magnets are anisotropic sintered magnets – the alloy is jet milled to a fine powder and is then compacted in the presence of a magnetic field to give it a preferred direction of magnetisation. The NdFeB magnets are then sintered to fuse the powder together before final machining and magnetising producing the completed super strength Neodymium magnet.

The Neodymium magnets are also known as Neo magnets, Neodymium Iron Boron magnets, Neodymium-Iron-Boron magnets, Neodymium Magnets, NdBFe magnets, NdFeB magnets, NIB magnets, Super Strength magnets and Rare Earth magnets (please note that SmCo is also called a Rare Earth magnet).

NdFeB is also called a Rare Earth magnet because Neodymium is a Rare Earth element, having a value of 60 on the Periodic Table. For note, there is nothing rare about Rare Earth magnets – the required elements are readily available and the NdFeB magnets are produced in several hundreds of tonnes each year.

The Neodymium Iron Boron magnets (NdFeB magnets) were developed just over 25 years ago and were first commercially available in 1984. Neodymium magnets were initially developed for voice coil motors in computer hard disk drives and this market still accounts for over 50 percent of all Neodymium magnets produced. Other applications include high-performance motors, brushless DC motors, generators, magnetic separation, magnetic resonance imaging, sensors and loudspeakers. They are becoming increasingly popular across a wide range of novelty products such as fridge magnets and all kinds of magnetically attachable gadgets for retail markets.

For note, our standard NdFeB (N42 magnet is the most popular grade) is rated to +80 deg C. We offer the whole range of Neodymium Iron Boron magnets, with Maximum Energy Product (BHmax) ratings from 27 MGOe to 52 MGOe (N27 to N52) and with a maximum operating temperature rating ranging from +60/+80 deg C to +220/+230 deg C (Nxx up to NxxVH / NxxAH, where xx is the Maximum Energy Product in MGOe).

e-Magnets Range of Neodymium Magnets

The complete standard range of neodymium magnets grades is as follows:

N27, N30, N33, N35, N38, N40, N42, N45, N48, N50, N52, N55, N27M, N30M, N33M, N35M, N38M, N40M, N42M, N45M, N48M, N50M, N27H, N30H, N33H, N35H, N38H, N40H, N42H, N45H, N48H, N27SH, N30SH, N33SH, N35SH, N38SH, N40SH, N42SH, N45SH, N27UH, N30UH, N33UH, N35UH, N38UH, N40UH, N27EH, N30EH, N33EH, N35EH, N38EH, N27VH/AH, N30VH/AH, N33VH/H and N35VH/AH.

The complete improved corrosion resistance range of neodymium magnets grades is as follows:

N27T, N30T, N33T, N35T, N38T, N40T, N42T, N45T, N48T, N50T, N52T, N27MT, N30MT, N33MT, N35MT, N38MT, N40MT, N42MT, N45MT, N48MT, N50MT, N27HT, N30HT, N33HT, N35HT, N38HT, N40HT, N42HT, N45HT, N48HT, N27SHT, N30SHT, N33SHT, N35SHT, N38SHT, N40SHT, N42SHT, N45SHT, L-N27SHT, L-N30SHT, L-N33SHT, L-N35SHT, L-N38SHT, L-N40SHT, L-N42SHT, L-N45SHT, N27UHT, N30UHT, N33UHT, N35UHT, N38UHT, N40UHT, L-N27UHT, L-N30UHT, L-N33UHT, L-N35UHT, L-N38UHT, L-N40UHT, N27EHT, N30EHT, N33EHT, N35EHT, N38EHT, L-N27EHT, L-, 30EHT, L-N33EHT, L-N35EHT, L-N38EHT, L-N27VHT / AHT, L-N30VHT / AHT, L-N33VHT / AHT and L-N35VHT / AHT.

For note, the L-NxxT versions offer the best corrosion resistance. Both the NxxT and L-NxxT versions are recent improvements and some grades may still be at late R&D stages which may affect mass production level availability. These versions are more expensive – please contact us for a quotation. Also, for maximum corrosion protection with strong magnetic performance, SmCo is a better choice.

Neodymium-Iron-Boron magnets contain approximately 75% iron and are therefore prone to corrosion. Protective coatings are applied to Neo magnets and the most common one is nickel plating (Ni-Cu-Ni; effectively a triple coating). The current range of coatings available is as follows:

Nickel-Copper-Nickel (Ni-Cu-Ni) [this is the standard coating], Everlube (6102G), Nickel (Ni), Epoxy (Black or Grey), Nickel-Copper-Black Nickel, Zinc (Zn), White Zinc, Coloured (red, green, blue, etc), Gold (Au) [this is actually NiCuNi plus Gold], Tin (Sn), Parylene C, Titanium (Ti), Silver (Ag) [this is actually NiCuNi plus Silver], Ni-Cu-Ni plus Rubber, Zn plus Rubber, Ni-Cu-Ni plus Parylene C, PTFE (“”Teflon®””) in black, white, silvery or grey, Copper (NiCu or NiCuNiCu), Titanium Nitride (TiN), Chrome (bright/standard or black), Ni-Cu-Ni plus PTFE, Zn plus Everlube, Ni-Cu-Ni plus Everlube, Ni-Cu-Ni plus Epoxy, Tin (Sn) plus Parylene C, Zinc Chromate, Phosphate Passivation, Uncoated (bare – recommend vacuum packing as well), Plastic encased (this fits around pre-coated magnets to give additional protection and is not hermetic). Other coatings may be possible – please let us know your requirements.

Neodymium magnets manufacturers

Apart from offering over 4250 combinations of NdFeB grade and finish, we also manufacture bespoke NdFeB sizes upon request. The NdFeB magnets vary from D1mm x 1mmA discs up to e.g. D50mm x 50mmA discs and up to 150mm x 150mm x 25mmA and 200mm x 130mm x 25mmA blocks. Standard NdFeB tolerances are +/-0.1mm. +/-0.05mm tolerances are also available for these Neodymium Iron Boron magnets.

We can produce smaller Neodymium magnets down to +/-0.005mm tolerances as part of our bespoke Precision NdFeB range (we would specify the tolerance that could be achieved for each shape but please note that the production runs would be subject to 100k minimum order quantity).

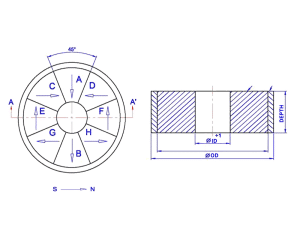

The NdFeB (NIB) magnets, in disc and ring forms, are usually axially magnetised (the round ends are the magnet poles). Diametrically magnetised discs and rings can be produced upon request (looking at the circular end face, the magnetism runs from the 12 o’clock position to the 6 o’clock position in diametrically magnetised magnets). Likewise, the rectangular blocks can be specially produced to be magnetised in any of the three axes (the magnets cannot be re-magnetised in another axis due to the method of production – the sintered NdFeB is anisotropic). Arcs, trapezoids and other shapes can generally also be produced. Bespoke Directions of Magnetisation within the magnet shape may also be possible (subject to confirmation) e.g. for Halbach Array assemblies.

Contact e-Magnets for Bespoke Custom Neodymium Magnets

If you require a bespoke/custom Neodymium Iron Boron (NdFeB, NIB, Neodymium, Neo) magnet or magnetic assembly, Technical Support or our NdFeB Technical Data Sheet, please contact us. And please feel free to browse our NdFeB-Info website (logo link to the bottom left of this page) for additional technical information on Neodymium Magnets.

Why choose us?

• 99% of orders delivered within 24 hours

• Over 1,500,000 magnets in stock

• More than 60 years experience