Pot Magnet Product Selection Guide

Pot Magnets are magnets which are housed inside a steel shell which offers maximum magnetic holding performance and improved protection for the magnet reducing the risk of breakage during use.

Bunting - eMagnets offers an extensive range of Pot Magnets which are perfect for a wide variety of uses within the scope of fixing and fastening applications including: marine, Point of Sale, window dressing, door / cupboard and gate clamps, false ceiling clamps, signs and banners, torque limited seals, jigs and fixtures, lighting fixtures and assemblies, marketing and exhibition displays, retrieval magnets, industrial fixings, etc.

This product selection guide has been created to guide you through the many available options to ensure you make the correct selection of Pot Magnet for your application

1. Select your Mounting or Fixing Type:

These magnets will have a countersunk hole in the front (magnetic) face to allow a simple countersunk screw to pass all the way through the magnet. This gives a flush finish on the face of the magnet with the threaded part of the fixing available of the other side of the magnet for fixing.

These magnets will utilise a ring magnet to create a space for the head of the fixing to sit clear from the magnet allowing the fixing to pass straight through the magnet from the magnet face side. This gives a flush finish on the face of the magnet with the threaded part of the fixing available of the other side of the magnet for fixing.

These magnets consist of a steel disc with a ring milled out for a ring magnet to be inserted plus a tapped through hole to allow the fixing to be threaded through the magnet. The through hole allows the the fixing to be turned past the magnet face to prize the magnet away from the structure to which it is magnetically held against.

These magnets feature an internally threaded stud or boss to enable a fastener to be attached. As the stud or boss forms part of the outer section of the Pot it allows more space for a larger magnet in the pot therefore increasing magnetic performance.

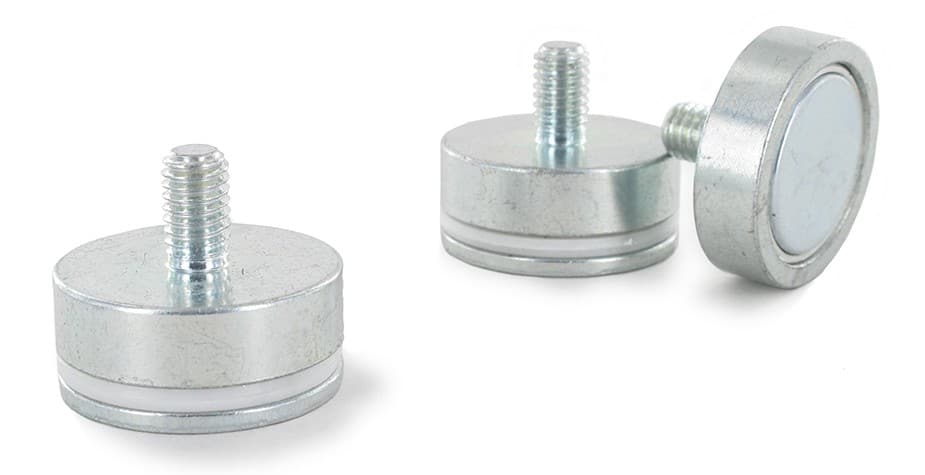

These magnets feature a stud or boss which is threaded and is perfectly suited for screwing the pot magnet in to existing tapped holes. Other threaded attachments can be screwed directly onto these magnets. As the stud or boss forms part of the outer section of the Pot it allows more space for a larger magnet in the pot therefore increasing magnetic performance

2. Select your Magnet Material:

External Threaded Stud

Corrosion Free, Long Lifecycle, Operate up to 250°C, Low Cost

Neodymium

Highest Performance, Operate up to 80°C, will corrode if the plating is damaged, higher cost.

Samarium Cobalt

Good performance, High corrosion resistance and will operate at high temperatures 250°C +.

Alnico

Stronger than ferrite, excellent resistance to corrosion, strong magnetic field operate at the highest temperature of any magnet, 450°C.

3. Consider the Finish or Coating of the Pot Magnet:

Chrome Plating

Offers excellent protection against corrosion.

Nickel Plating

Offers protection against corrosion.

Stainless Steel

Highest level of corrosion resistance - perfect for marine applications.

Painted

Historically Alnico magnets have typically been painted Red. This offers slightly enhanced protection to surface corrosion but is mainly aesthetical.

Rubber Coated

Offers much better shear (sliding) resistance. Rubber coating also offers greater protection to the surface you are fixing the magnet to ie painted surfaces or highly polished surfaces

4. Consider the Size and Depth of the Pot Magnet:

It is important to consider both the Diameter and Depth of the Pot Magnet to ensure it will work with your desired application. Generally the greater the size of the magnet the greater the performance. Remember, Neodymium offers greater performance so a smaller Neodymium magnet can easily out perform a much larger magnet made from another magnetic material.

5. Consider the Pull Force of the Pot Magnet:

Each Pot Magnet within our range has a Pull Force displayed in Kgs which gives a guide to the magnets performance in a direct pull test. This will allow you to easily compare the difference between various Pot Magnets. The Pull Force of a magnet will be reduced where an air gap is present between the face of the magnet and the surface it is attracting including painted, corroded and uneven surfaces. The smoother the surface the better the magnet will perform

6. Consider if you require Hooks or Eye Bolts:

Pot Magnets lend themselves perfectly for use with hooks and Eye bolts. We now stock a range of Hooks and Eye Bolts available in a number of thread sizes to accompany our range of Pot Magnets.