Soft Magnetics are one of our most popular and important products. But we still often get asked, ‘What are Soft Magnetics?’ Simply, soft magnetic materials are those that can be easily magnetised and demagnetised and their primary use is to enhance and/or channel the flux produced by an electric current.

Soft Magnetics Characteristics

Soft magnetics have many characteristics that perfectly suit many electrical applications. The low coercivity of soft magnetic materials (typically less than 1000 Am-1) means that it is relatively easy to magnetise and demagnetise the material. Soft magnetic materials are also characterised by high permeability, which is a measure of how easily a material can be magnetised.

Soft Magnetics AC and DC Applications

The characteristics of soft magnetics lead to their use in a diverse range of applications. The types of applications fall into two categories: AC and DC. In a DC application, the material is magnetised to perform an operation before being demagnetised. Whereas in AC applications, continuously cycling of the material, from being magnetised in one direction to the other, occurs throughout the period of operation, e.g. a power supply transformer.

Permeability is likely to be the main the main consideration for material selection in DC applications such as in shielding applications where channeling of the flux must be through the material.

For AC applications, the key consideration is the amount of energy lost in the system during the cycling of the material around its related hysteresis loop. A reduction of the intrinsic Coercivity reduces the hysteresis losses.

Soft Magnetic Applications

Soft magnetic materials are essential components of many modern electronic and electrical devices. They play a vital role in the generation, transmission, conversion, and storage of electrical energy. The diverse range of applications for Soft Magnetics includes:

- Transformers and inductors: Soft magnetic materials in transformers and inductors store and release magnetic energy. This energy transmits and converts electrical power;

- Electric motors and generators: Soft magnetic materials in electric motors and generators create and guide magnetic fields. These magnetic fields and forces rotate the motor shaft or generate electricity;

- Magnetic recording devices: Soft magnetic materials in magnetic recording devices, such as computer hard drives and tape recorders, store data.

- Magnetic shielding: Soft magnetic materials shield electronic devices from magnetic fields. This is useful for protecting devices from interference from other magnetic fields, such as those generated by power lines and motors.

Soft Magnetic Materials

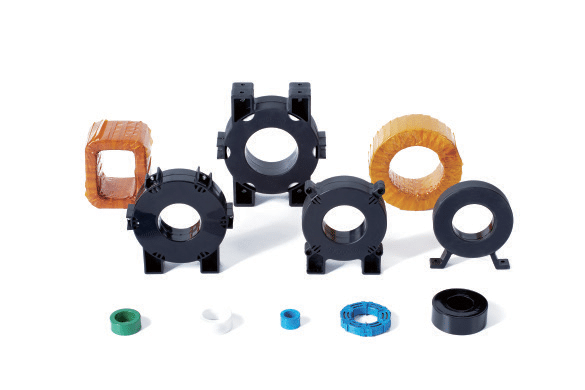

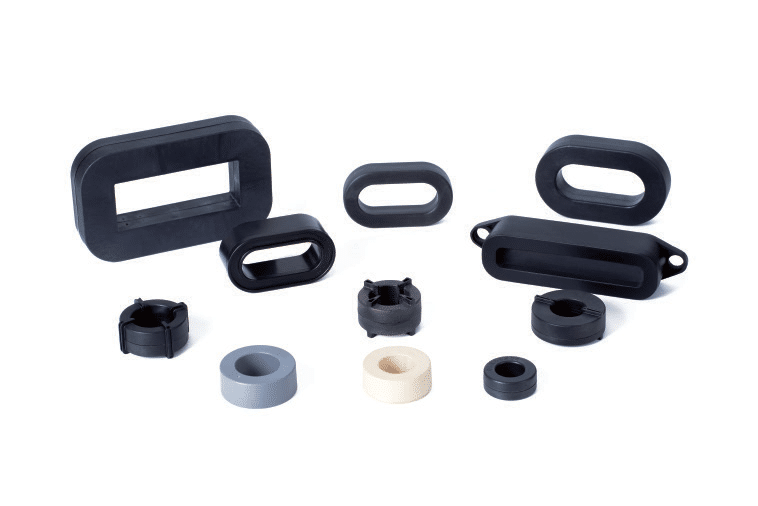

At Bunting, there are three (3) categories of soft magnetic materials:

- Metal cores – these are made of metal strips which can be wound or stamped to make various, but limited, shapes for relatively low frequency applications up to 50KHz. The only exception is for EMI suppression applications up to several hundred megahertz. There are four (4) main types of metal cores:

- SiFe – Silicon iron cores, which are used for 50/60 Hz applications such as mains transformers, high power inductors and motors;

- NiFe – Nickel iron cores for high permeability applications, which are predominantly shielding and suppression applications;

- Amorphous and Nanocrystalline cores – Power transformer applications up to 50kHz. Additionally, in the case of nanocrystalline, these cores can provide a lower cost alternative to NiFe for electromagnetic compatibility (EMC) and high permeability applications. Cobalt base amorphous is also available and provides the highest permeability and lowest core loss, but is higher in cost due to the cobalt content;

- Cobalt iron – This metal core has very good magnetic properties, including highest magnetic saturation, but is higher in cost due to the cobalt content. Subsequently, the cobalt iron core is generally used in technically demanding niche applications, such as encountered in the military and aerospace industries;

- Powdered cores – These cores, composed of compacted insulated iron particles, are mainly used for power chokes due to the resulting distributed gap. Standard iron powder and several alloyed versions reduce power losses, audible noise and have improved DC bias properties. Soft Magnetic Composite (SMC) is a new emerging materials using high purity iron particles, replacing electrical steel in some motor applications due to the material’s superior high frequency characteristic. Also, SMC has superior flexibility of core shape for more intricate designs;

- Ceramics – Soft ferrite cores are classed as ceramics due to synergies in the manufacturing process and the material’s hard but brittle nature. There are several subcategories, of which the main ones are MnZn for power and high permeability applications, and NiZn for high frequency applications and those requiring very high resistivity. Other specialist categories include microwave ferrites;

For more information, please contact our technical sales team via the contact page on our website – Contact Bunting