Neodymium Iron Boron Rare Earth Magnets are used everywhere and are among the strongest permanent magnets. But what exactly are they?

The Neodymium Iron Boron Magnet (Neo, Neodymium, NdFeB, NIB, or Neomagnet) is the most widely used type of permanent rare earth magnet. The high-strength permanent magnet is made from an alloy of neodymium, iron and boron to form the Nd2Fe14B tetragonal crystalline structure.

Discovering the first Neodymium Magnet

The first Neodymium Magnet was developed independently in 1984 by General Motors (GM) and Sumitomo Special Metals as they investigated alternatives to the costly Samarium Cobalt Magnets. General Motors (GM) commercialised isotropic neodymium powder to produce bonded magnets. Sumitomo’s development focused on full-density sintered neodymium iron boron magnets. Since the discoveries, neodymium magnets have become a feature of our daily lives and are present in mobile phones, computers, and even kitchen cupboard catches. They are also essential for renewable energy, including wind turbines and electric cars.

Neodymium Magnets also help us recycle when used as a fundamental part of a Magnetic Separator or Eddy Current Separator as manufactured by Bunting. In recycling, neodymium’s high-strength magnetic forces are used to both attract and repel metals to enable separation and recovery.

Neodymium Magnet Production

China dominates the global production of Neodymium Magnets (95%) due to the location of many of the raw material reserves. This reliance on China is of global concern highlighted when, at the end of 2010 and into 2011, the Chinese Government sent shock waves worldwide when they slashed export quotas for rare earth magnets and dramatically increased prices for foreign customers. This lasted until 2015 when China lost a World Trade Organisation case brought by the USA, and other trading partners, and the restrictions were relaxed.

Neodymium Iron Boron Magnets are produced using two manufacturing methods:

- Classical powder metallurgy or sintered magnet process, which produces a stronger and robust Rare Earth Magnet but is more expensive to manufacture;

- Rapid solidification or bonded magnet process, which is cheaper but does not have the same magnetic strength;

Recycling Neodymium Iron Boron Magnets

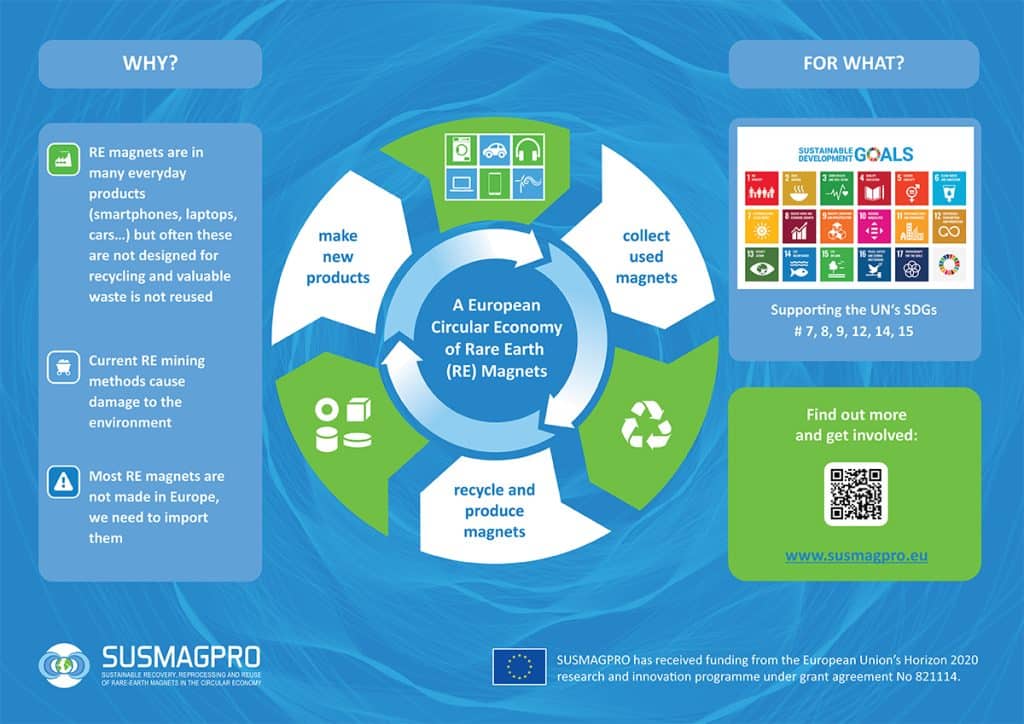

One way to reduce the reliance on China is to recover and recycle neodymium iron boron magnets. Bunting has worked with a number of other magnetics organisations and research bodies in the EU-funded SUSMAGPRO project, assessing recycling processes and technology.

Neodymium Iron Boron Magnets are supplied in an unlimited range of shapes and sizes for a diverse number of applications that continues to grow. There is no sign of a slowdown in demand, and there is only a question of supply and price in the longer term.

Magnet and Magnet Assembly Design

Bunting designs, manufactures and supplies a wide range of soft magnetics, magnets, magnet setters, magnetisers, and magnetic assemblies. Many are bespoke for specific applications.

A complete range of Neodymium Iron Boron magnets, including discs, rods, or blocks, are available to purchase online.

For further information, please contact us via:

Phone: +44 (0) 1442 875081

Email: emagnets@buntingmagnetics.com

Via Bunting-eMagnets for online purchase of Magnets and Magnetic Technology